WZS 70 REINECKER

Cutting tool grinding machine

- Large workspace at small machine dimensions.

- Various clamping systems available for maximum flexibility and short set-up times.

- High resolution direct measuring system on 5 axes.

- Direct drive systems (liquid cooled) for grinding spindle and rotating axes.

- Linear axes with direct drive for highly dynamic requirements optionally available.

- Easy access to service-related areas for simple and quick maintenance.

- Further optional components and features available for individual needs and process optimization.

- CNC control NUM Flexium+ with powerful NUM DriveX and integrated safety architecture NUM Safe.

Brochure

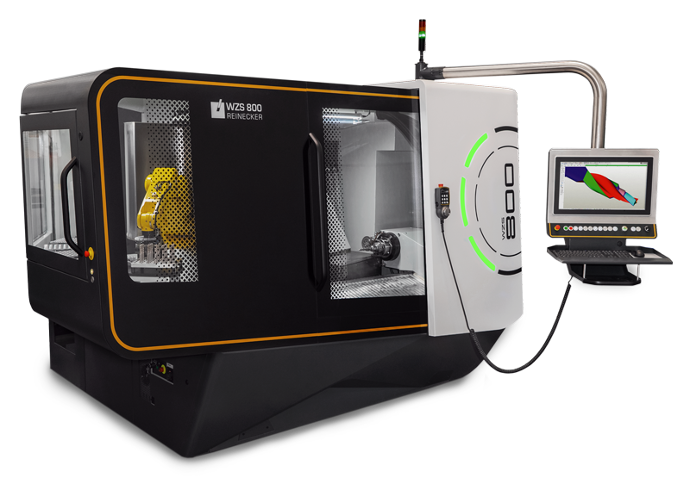

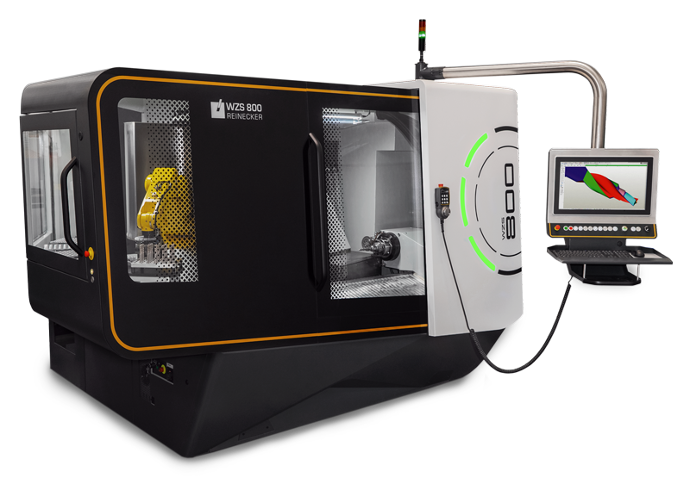

WZS 800 REINECKER

Cutting tool grinding machine

- Reliable results: Polymer concrete machine base for optimum vibration damping, excellent rigidity, thermal stability, and efficient chip removal flow.

- Maximum precision: Measuring systems with high resolution close to the grinding point.

- High power density: Grinding spindle and rotary axes with liquid-cooled direct drives.

- Long autonomy periods: 12-wheel grinding wheel magazine and automatic loader.

- Optimized processes: Optional linear drive and 14-wheel grinding wheel magazine.

- Ergonomics for maintenance and service: Easy, fast maintenance and repair due to good accessibility to service-relevant areas.

- Customized solutions: A large number of further option modules allow the implementation of different requirements.

- Innovative design: Integrated operating status light with long-distance effect in the front area for quick recognition of operating statuses.

- Up-to-date security: Operating mode selector switch with RFID-coded recognition of users and their authorization, as well as integrated NUM-Safe safety architecture.

- User-friendly operation: Height-adjustable control panel with 24″ multi-touch screen and NUMROTOplus®programming system with 3D simulation and collision detection.

- NUM Flexium+: CNC control with powerful NUM DriveX drives.

Brochure

RS 50 REINECKER

Cylindrical grinding machine

- Combining cylinder and cone surface production with points, chamfers, radii and steps.

- High accuracy contours via peel grinding.

- 3-axes kinematic.

- Grinding unit with liquid-cooled motor spindle and 80 degree positioning range.

- Two different grinding wheels on one flange.

- Clamping in chuck, various systems and sizes available.

- On-board-probe for tool position.

- Automatic loading systems available (options).

- CNC control NUM Flexium+ with powerful NUM DriveX and integrated safety structure NUM Safe.

Brochure